Designers and architects all over the world are now adopting 3D Printing for the creation of almost all types of products and structures! It’s a technique that has gained a lot of momentum, owing to its simple and innovative nature. But designers aren’t employing 3D printing only to create basic models, they’re utilizing this technique in mind-blowing ways as well! From 3D printed artificial coral reefs to a menacing automotive design with 3D printed parts, the scope of this dependable technique is unlimited! In fact, did you know, lunar habitats for the moon are being 3D printed as well? There’s honestly nothing that cannot be 3D printed these days, the possibilities are endless, and we’re super excited to see what else is in store! For now, dive into this collection of humble yet groundbreaking 3D printed designs!

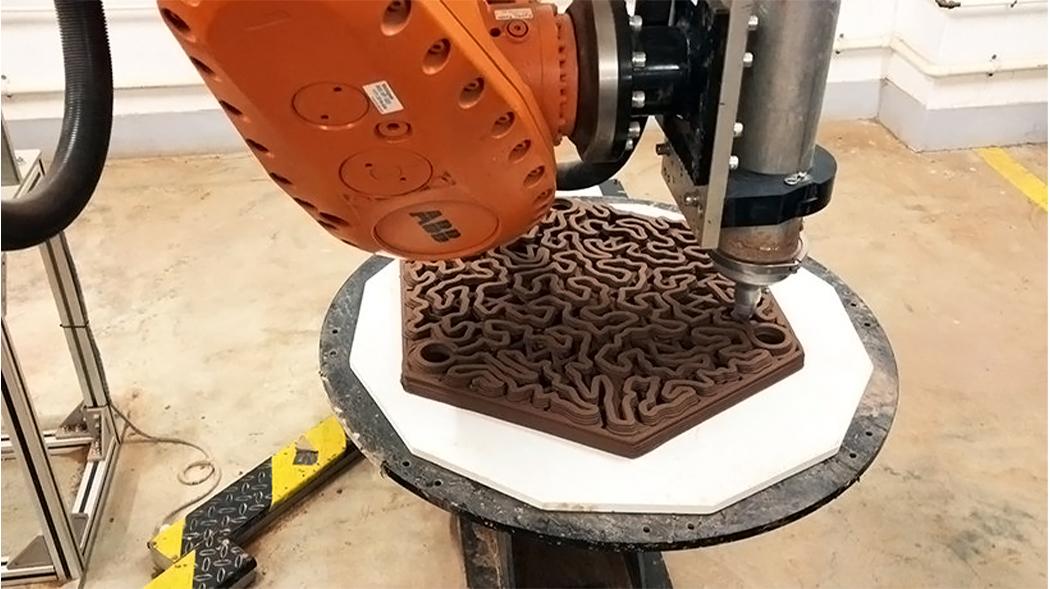

Hong Kong saw an 80% decline in the coral population in Double Island, Sai Kung, over the past decade and that drove the team to come up with a solution that would not only help that region but also the rest of the world that was blessed with corals. The team from Swire Institute of Marine Science (SWIMS) of the University of Hong Kong (HKU) and its Robotic Fabrication Lab of the faculty of architecture worked together to 3D print terra-cotta tiles that will act as artificial reefs. The result is a mesmerizing, organic swirl of line and negative space that reads like a burnt orange topographic map—and mimics the natural patterns of the coral itself. Why terra-cotta? It’s highly porous with “nice surface micro-texture” for marine organisms to latch on to, says team member Dave Baker, and an eco-friendly alternative to conventional materials such as cement or metal, the HKU team says.

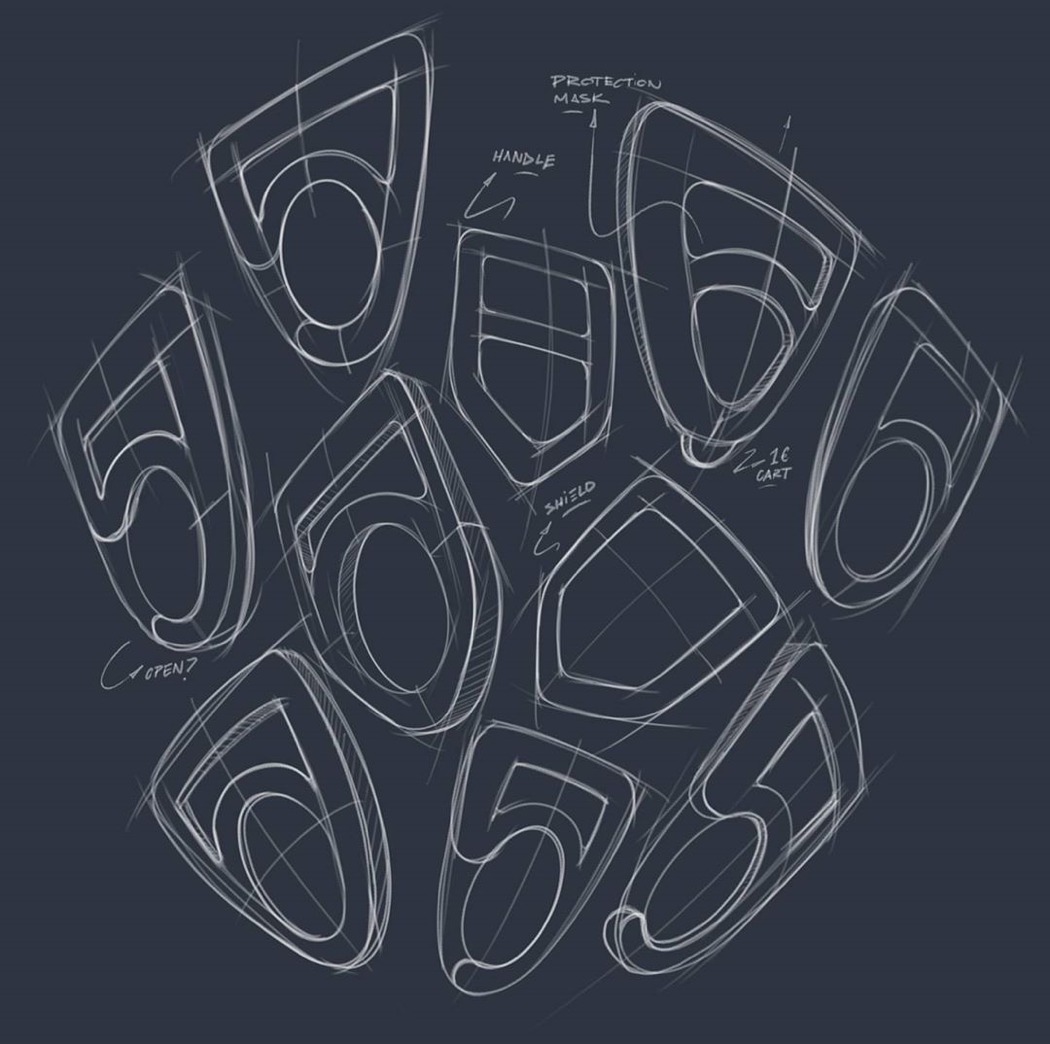

The shape of the handy tool called MH-19 is inspired by protection masks and has solved yet another problem using design. Gloves are single-use items that generate more waste if used by everyone to do everyday things. Gloves can be left aside for the healthcare professionals who need them the most while we can use reusable handles like this for our daily essential outdoor tasks. Innovation has the power to be simple yet mighty effective in its purpose. 3D printers are currently a valuable tool in this fight and the global design community is doing everything they can to support the healthcare professionals, engineers as well as the general public through their creativity.

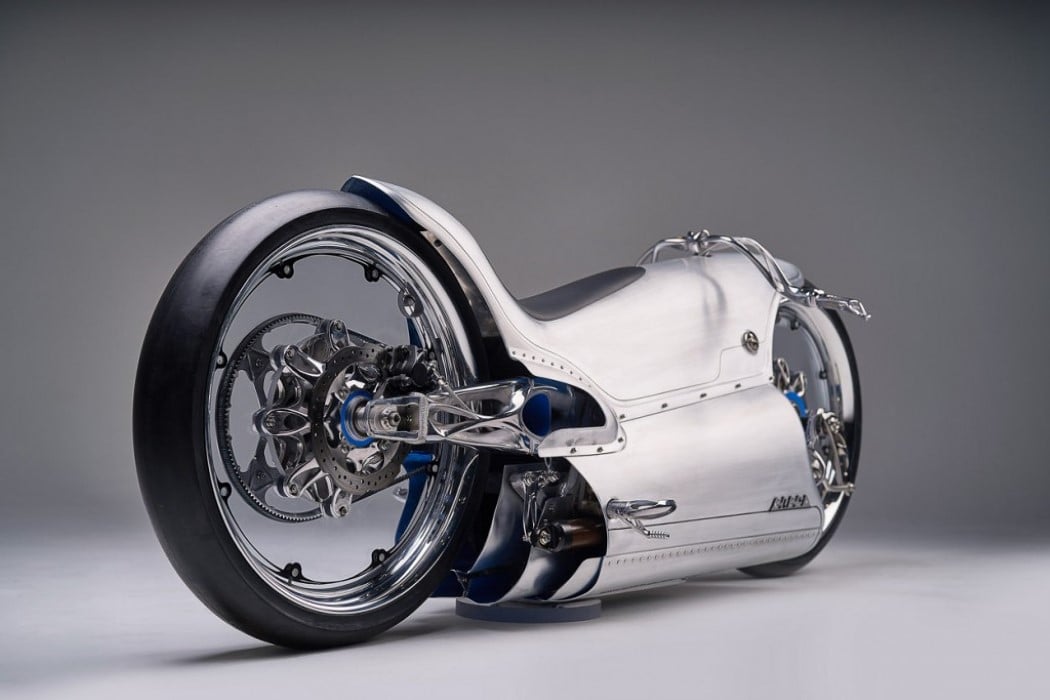

The 2029 e-bike brings art-deco and automotive design into the future, with its unusual combination of clean-cut geometric shapes brought about by sheet-metal fabrication, along with bone-inspired generative-design details 3D printed in metal. The bike is an amalgamation of styles that pays a hat-tip to the revolutionary design of the 1929 Majestic, built by George Roy. Ninety years later, Bryan Fuller and his team at Fuller Moto decided to push boundaries with bike design. Created as a commissioned piece for the Haas Moto Museum and Sculpture Gallery, the bike incorporates design trends and technologies that are indicative of the future of automotive design. The stunning 2029 comes with an electric drivetrain, fully enclosed aluminum body, hub-centric steering, transparent PolyCarbonate wheels, and 3D printed bike parts, furnished out of Titanium.

NIVEA’s parent company is German giant Beiersdorf and they are on a mission to reduce packaging waste by minimizing and closing their material cycles. And for NIVEA that meant launching a shower gel refill station! Now it is a good first step and has its pros but also has some cons. The biggest con is that shower gels themselves are not good for the environment and there is no way to know how many bottles actually get rinsed clean before they are recycled – otherwise, it doesn’t work. Shower gels also need a lot of water to be made, and as climate change makes the world hotter/drier, the water crisis is already a big issue in many countries. A solution to that? Bar soaps! NIVEA makes those too, they use less water and can be packaged in the recycled paper – that is the real solution but if this refill station reduces some plastic waste and sparks a movement for the brand to take bigger steps, then we are here to see it. The prototype is going to be tested in select locations where the brand will gather data on how consumers are interacting, feeling, reacting to the concept of reusable bottles. The prototype machine was made with their in-house 3D printers. NIVEA hopes that with this refill station they will make it convenient for consumers to reuse containers and reduce plastic usage.

Say hello to Timor, Sargasso, and Celebes, three members of John’s Coral Lighting Collection. Inspired by different styles of corals, the lamps come with varying aesthetics that reflect the visual characteristics of each coral type. The way John went about creating these unique lights was to first develop the computational design algorithms that mimic growth patterns found in nature. “The lighting collection is my way of paying tribute to the beauty of the ocean. As a veteran surfer, I’ve experienced the power and beauty of the ocean while enjoying each wave as its own unique moment in time. One of many magical living structures in our great oceans is coral. With a diverse range of colors, shapes, and scales, coral is an entire ecosystem of thriving life. My lighting celebrates this life”, says Mauriello.

What we really need is for everyone to wear face-masks that prevent the transmission of germs. What we DON’T need is for those face-masks to make it harder for us to breathe, right? As you inhale, most flimsy fabric masks collapse inwards because of the negative air pressure created inside the mask… it’s honestly something most people can deal with, but if you’re someone with pre-existing respiratory difficulties, it could make regular breathing rather difficult. The Cannula mask avoids this problem with its reinforcing endoskeleton. A thin plastic grille, this skeleton gives the mask its defining structure, preventing it from pressing against your face the same way a hanger prevents clothes from getting crushed by retaining its shape. Designed to be worn by people with respiratory difficulties, the endoskeleton even comes with a hollow spine that allows you to plug a nasal cannula into it, letting you direct fresh oxygen right to the wearer’s nose; effectively allowing them to inhale and exhale freely without worrying about a flimsy mask smothering them every time they try to breathe.

A lot of moments in rock history are defined by the iconic guitar-smash… and while I personally don’t think it’s particularly nice to smash musical equipment, what if you designed a guitar that, if you look at the image immediately below, couldn’t be smashed? That’s what Sandvik decided to do. Designed to show off their advanced titanium additive printing techniques (and also their engineering prowess), they designed the world’s first guitar that can’t be smashed. Literally. Many have even tried, including rockstar Yngwie Malmsteen, who managed to wreck his stage amps and monitors but couldn’t get the guitar to even as much as deform. Sandvik partnered with guitar-designer Andy Holt over what sounds like a pretty unusual design brief… Designing an electric guitar that was virtually indestructible, but also sounded incredibly good. The design process included hours of analyzing footage of guitars being smashed (many by Malmsteen himself) to analyze the biggest points of weaknesses.

The TWS earphones’ unique shape comes with a specially designed 3D acoustic chamber that helps make the audio sound richer, with better, more distinct basslines… while also helping reduce sound distortion as well as providing organic noise isolation of up to -35 db, allowing it to rival the Airpods Pro’s active noise cancellation tech just through its ergonomic design. The amount of careful consideration built into the Lytte HarmoniQ is truly remarkable. Each earphone casing is meticulously 3D printed using DLP printing tech (a feature that allows it to have that unique acoustic chamber shape) and hand-polished to look as remarkable as it does. Just like most smart earphones, the Lytte HarmoniQ supports iOS as well as Android integration, with the ability to tap, double-tap, and long-press to control music playback as well as smartphone functions (including summoning the phone’s voice AI).

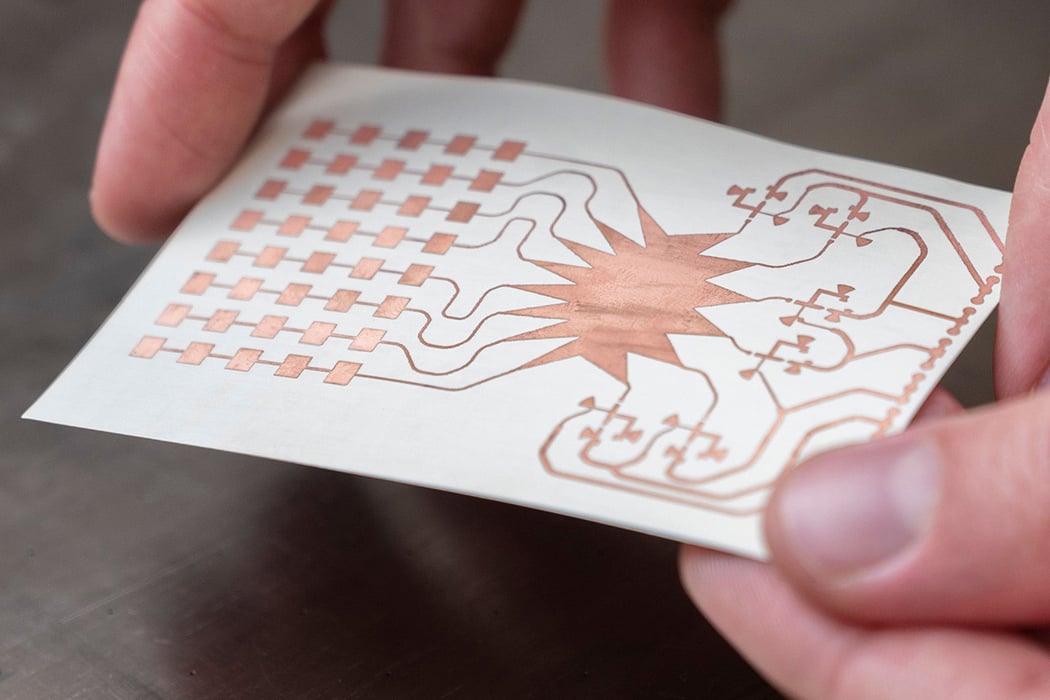

Harvesting abundant sources of renewable energy and then converting them into something valuable has been the quest humankind has been on for decades. This makes even more sense in current times when we are on the brink of exhausting earth’s vital resources, causing unrepairable harm to the planet. As scouts of this very quest, the team at Georgia Tech’s ATHENA lab has created a 3D-printed energy harvesting antenna that’s capable of garnering electromagnetic energy of the 5G signals to juice modern-day gadgets. The technology is literally about putting the overcapacity 5G network bandwidth to judicious use – turning it into a wireless power grid that could shape the future of our relentless energy requirements for IoT devices or mobile devices. They’ve created a flexible Rotman lens-based rectifying antenna (rectenna) that can collect the millimeter-wave in the 28-GHz band – the first of its kind. Previously there have been attempts to harvest the 24 or 35 GHz frequencies, but they were not practical since they only worked when they are in sight of the 5G base station.

Does your company’s conference room need a little inspiration? This far-out office furniture is designed to liven up your workspace. It’s entirely 3D-printed which results in smooth transitions and curves throughout. With its three-dimensional Voronoi pattern, it sports an organic, liquid-like shape that’s sure to be a conversation starter and something to get your team’s wheels turning.