Now I’m not much of a climber (I just about take the stairs), so I’ll defer to the experts at Athos who highlight how problematic current climbing shoes are. Designed specifically for being able to grip onto rocks, ledges, and the tiniest of cracks in a very vertical surface, climbing shoes are made for traction, not comfort, which is why a lot of climbers end up with foot aches and injuries after wearing climbing shoes for too long. When climbers buy shoes, they always look for the tightest fit (for better performance), often wearing shoes that are up to 2 or even sometimes 4 sizes smaller than their actual size, resulting in bruised or sometimes even disfigured feet in the long run… Athos’ solution to this? 3D printing shoes that are designed to perfectly fit your feet.

Started as a project at Spain’s ELISAVA institute, the designers were searching for innovative applications of additive manufacturing. Being avid climbers, their eureka moment came when they realized that additive manufacturing (or AM for short) could easily help create the perfect climbing shoe. By using AM technology, the designers were able to custom-build out each shoe considering inputs like the wearer’s foot shape, needs, and type of performance.

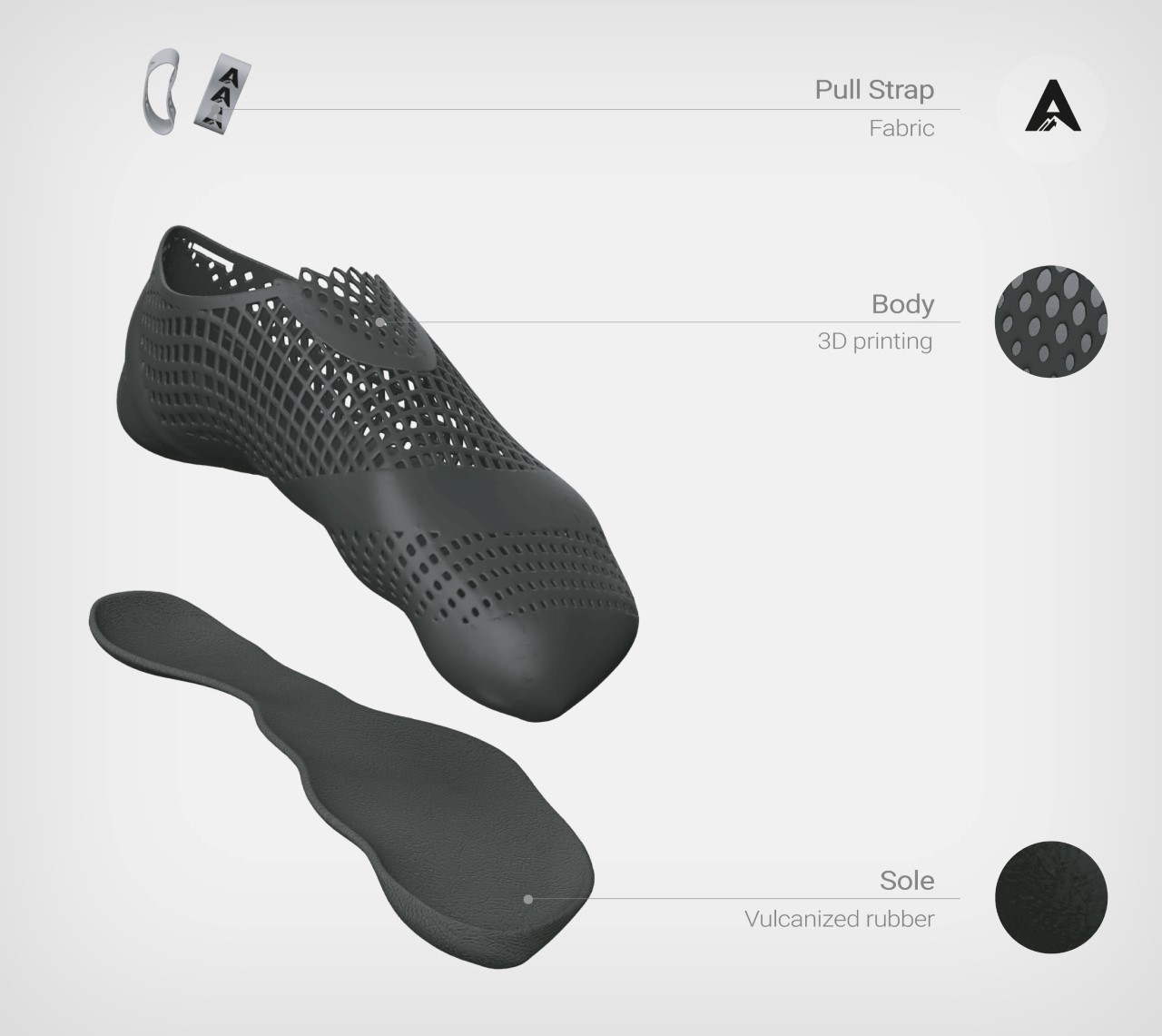

The Athos shoes are made from two broad materials – a flexible, foot-hugging body made from 3D-printed TPU, and a two-part outsole crafted from vulcanized rubber. The TPU acts almost as a second skin, flexing with your foot’s movements while staying breathable (thanks to a unique perforated design), while the vulcanized rubber gives the shoes their signature traction and grip, allowing you to easily hold onto small ledges and rocks while you climb. Each shoe is custom-made to fit the wearer, making them unique. The additive manufacturing technique also helps dramatically reduce the number of processes and materials by more than 50%.

The Athos workflow has 4 steps: 1. Feetscan of the user, done within the Athos app. 2. Personalization and customization: type of shape, style of climbing, color, name, etc. 3. Printing out the shoe’s body, post-processing, and assembling parts. 4. Delivery to the user.

The shoes are on track to be prototyped and tested out by 10 professional climbers in January 2022. If everything goes according to plan, Athos hopes to secure SEED funding by March and start building climbing shoes for regular consumers across Spain by the end of next year.

A National Winner of the James Dyson Award, Athos now progresses to the international round of the award program, with the results being announced on October 13th.

Designers: Team Athos

![]()